When two companies have innovation, research and quality as their common denominator, only a fruitful collaboration can arise.

This is what happened between +CIM4.0 and the Team Policumbent, a student team of the Politecnico di Torino that deals with the design and production of a recumbent and faired prototype bike.

The Policumbent team is an active member of the IHPVA (International Human Powered Vehicles Association), which every year organizes a race open to all its members in the USA, specifically in Battle Mountain, Nevada. The Team aims to achieve important speed records recognized worldwide every year, and this year there will be 3 prototypes that will aim for the world speed record in many categories: female, male and handbike. Precisely for this last prototype, on which the team has concentrated on this last year of production, it has relied on CIM4.0 for the production of AM (Additive Manufacturing) parts, obtaining functional pieces with a fast and optimal production.

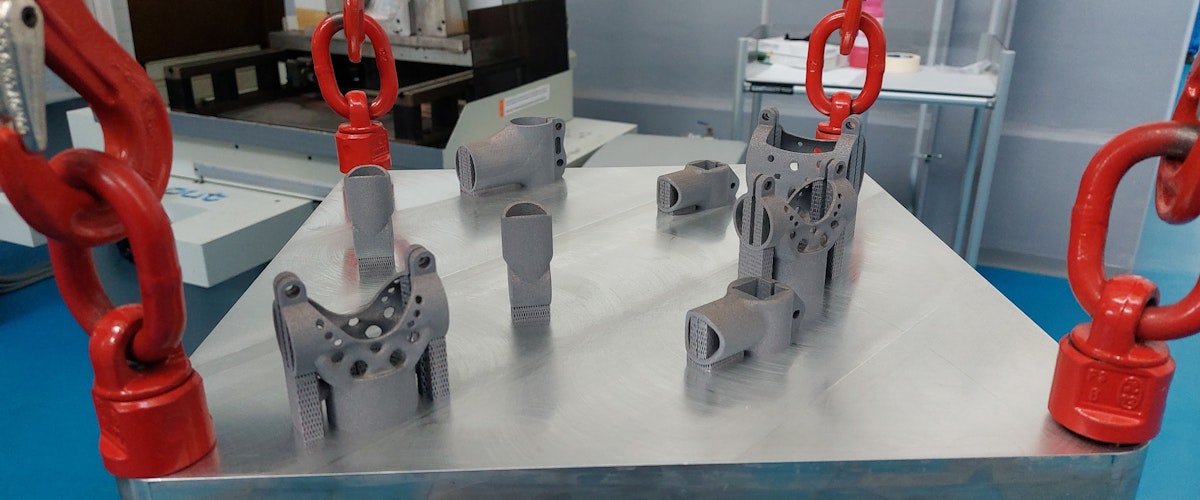

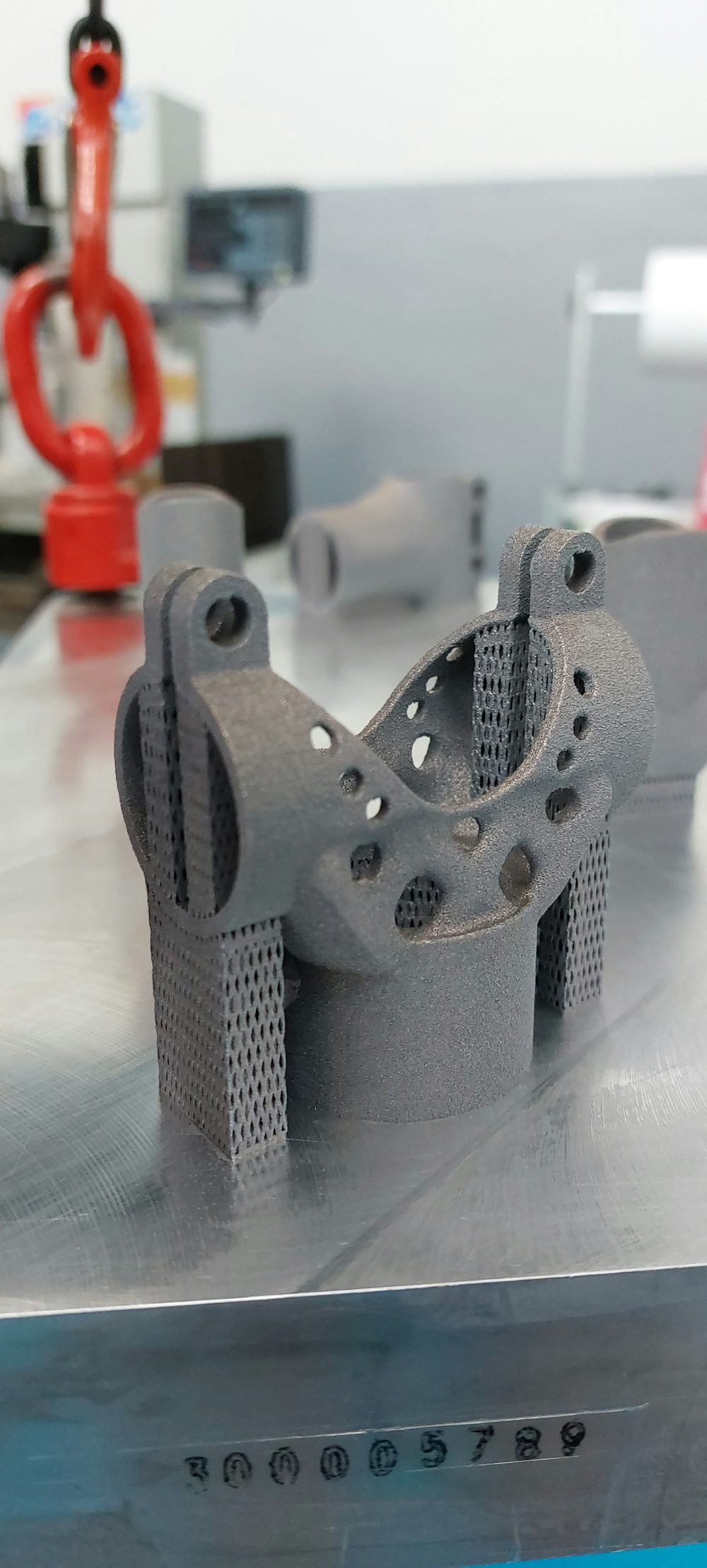

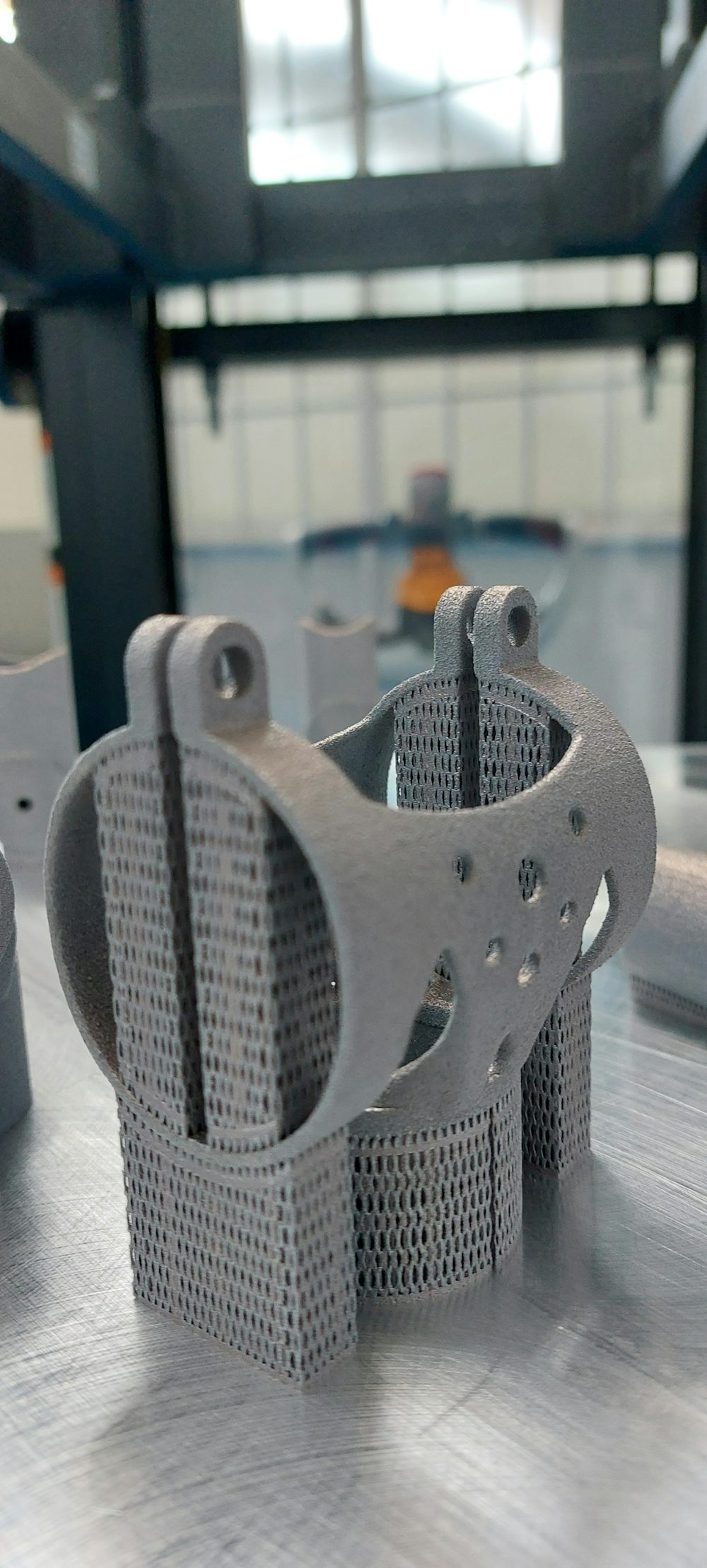

The young students of the team were able to gain experience in what the world of DfAM (Design for Additive Manufacturing) is, and on the other hand CIM4.0 had the opportunity to meet curious and enterprising students, as well as an extremely interesting and innovative project. The components made for Policumbent will be mounted on 2 of the 3 prototypes that will be brought to the United States in a few weeks: for Cerberus (handbike) a headset collar and cranks have been made, which connect the carbon frame to the steering tubes , again in carbon, while a collar and a steering support have been created for the TaurusX (female).

The guys on the team managed the entire design workflow, for which they defined the functionalities of the pieces, evaluated the CAD geometries which were then refined with topological optimizations thanks to finite element analysis software, following and optimizing the design in function of the manufacturing. Once they arrived in the company, analyzing ideas with their new colleagues , they further modified their result, reaching reliable and robust models. Finally, production was entrusted to the expertise of CIM4.0 and its AM pilot line.

The pieces were produced with EOM M-400-4, one of the machines present in the plant that processes pieces produced with large powders and 4 lasers for metal melting, to reach high production capacities. Among all the powders that can be treated with the aforementioned machine, the aluminum alloy AlSi10Mg was chosen, an excellent compromise between rigidity and lightness, in line with the aim of having a reliable racing vehicle at high speeds. The technology used is the laser powder bed technology: in short, this technology deposits liquid metal which then solidifies in successive thicknesses of the order of micrometers, ensuring enviable precision, saving the component from the traditional post-production processes to treat the roughness, which can be grinding and lapping.

The Policumbent team was extremely satisfied with the fruitful participation and thanks +CIM4.0 for their competence, professionalism and availability. For its part, +CIM4.0 proves once again to be the protagonist of an evolutionary process in the industrial field that sees a transformation of industries from traditional to 4.0 and highly digitized industries.